The simple pleasure of fresh, air-popped popcorn is a household favorite, offering a quick and healthier snack option. Yet, like any electrical appliance, an air popcorn maker requires mindful operation to ensure safety and longevity. A primary concern for many users is the risk of overheating, which can not only damage the unit but also pose a fire hazard. This comprehensive guide will equip you with essential safety tips to prevent overheating, ensuring your popcorn machine operates safely and efficiently for countless movie nights and snack times.

Understanding Why Air Poppers Overheat

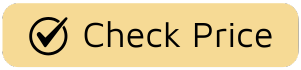

Air poppers work by circulating extremely hot air around popcorn kernels, causing them to pop without the need for oil. This process naturally generates a significant amount of heat. However, several factors can cause this heat to become excessive, leading to overheating. Obstructed airflow is a major culprit, preventing the internal cooling mechanisms from working effectively. Continuous operation without adequate cooling time between batches can also cause heat to build up beyond safe levels. Furthermore, a lack of proper cleaning, the accidental introduction of incorrect ingredients like oil or butter into the popping chamber, or a pre-existing fault within the unit can all contribute to dangerous overheating.

An air popper in operation, showing hot air circulation and potential overheating points.

An air popper in operation, showing hot air circulation and potential overheating points.

Essential Safety Tips for Air Poppers

To keep your air popper running smoothly and safely, integrate these crucial practices into your popcorn-making routine.

Always Ensure Clear Airflow and Ventilation

Air poppers rely heavily on proper air circulation to dissipate heat. It is critical to keep all air intake and exhaust vents completely unobstructed. Before each use, quickly check that no dust, stray kernels, or debris are blocking these openings. Additionally, always place your air popper on a stable, flat, heat-resistant surface, away from walls, cabinets, or other items that could impede airflow around the machine. Good ventilation is your first line of defense against overheating.

Never Add Oil, Butter, or Shortening to the Popping Chamber

This is perhaps the most vital safety rule for air poppers. These appliances are specifically designed for dry kernels and hot air only. Introducing oil, butter, shortening, or any other liquid or semi-solid fat into the popping chamber will cause significant hazards, including fire and severe damage to the unit. The high heat of the air popper can cause these substances to smoke, ignite, or create a hazardous mess.

Adhere Strictly to Manufacturer’s Instructions

Every air popper model comes with a user manual, and for good reason. It contains specific guidelines tailored to your appliance’s design and capabilities. Always read your owner’s manual thoroughly before the first use and refer to it for any questions. Pay close attention to recommended batch sizes, maximum operating times, and specific cleaning instructions. Deviating from these guidelines can increase the risk of overheating and reduce the lifespan of your machine.

Avoid Continuous Back-to-Back Batches

While the allure of endless popcorn is strong, most air poppers are not built for continuous operation. Running batch after batch without a break can quickly lead to an accumulation of heat within the unit, pushing it beyond safe operating temperatures. It is generally recommended to allow your machine to cool down completely for at least 10-15 minutes between uses. This cooling period is essential to prevent heat buildup and protect the internal components from damage.

Never Leave Your Air Popper Unattended During Operation

An air popper should always be under active supervision while it is in use. The popping process is relatively quick, but issues like smoking, unusual noises, or the smell of burning can arise unexpectedly. Staying present means you can react immediately to any potential problems, unplugging the machine at the first sign of trouble. This prevents minor issues from escalating into serious safety concerns.

Use Only Dry Popcorn Kernels

Ensure you are using fresh, dry popcorn kernels specifically intended for air popping. Old or improperly stored kernels might contain excess moisture, or they might not pop efficiently, leading to prolonged operation and increased heat generation within the machine. Avoid any kernels that are broken or have an unusual appearance.

Regular Cleaning and Maintenance

A clean air popper is a safer and more efficient air popper. After each use and once the unit has completely cooled, wipe down the popping chamber and exterior. Regularly remove any unpopped kernels, kernel fragments, or debris that might accumulate. Such buildup can interfere with heating elements, block vents, or even pose a fire risk if left unchecked. Proper cleaning prevents blockages and ensures optimal performance.

Person cleaning an air popcorn maker, emphasizing safety and regular maintenance.

Person cleaning an air popcorn maker, emphasizing safety and regular maintenance.

Inspect Your Appliance Regularly

Before each use, take a moment to visually inspect your air popper. Check the power cord for any signs of fraying, cuts, or damage. Examine the plug for bends or discoloration, and look over the unit itself for any cracks, melting, or unusual wear. If you notice any signs of damage, do not operate the appliance. A damaged cord or unit can be an electrical hazard and may contribute to overheating.

What to Do If Your Air Popper Shows Signs of Overheating

Even with the best precautions, appliances can sometimes malfunction. If your air popper begins to smoke, emit a burning plastic smell, makes unusually loud noises, or simply feels excessively hot beyond its normal operating temperature, take immediate action:

- Unplug Immediately: Disconnect the machine from the power outlet at once.

- Do Not Touch Hot Surfaces: The unit will be extremely hot. Allow it to cool down completely in a well-ventilated area before attempting to handle or inspect it.

- Inspect for Damage: Once cool, carefully examine the unit, cord, and plug for any visible signs of damage, such as melted plastic, scorched areas, or frayed wires.

- Discontinue Use If Damaged: If you find any damage, or if the overheating issue persists after cooling, it is safest to discontinue use and consider replacing the unit. Consult the manufacturer’s troubleshooting guide or contact customer support if you’re unsure.

Conclusion

Enjoying perfectly popped, healthy popcorn at home is a simple pleasure that should always come with peace of mind. By consistently applying these essential safety tips—ensuring clear ventilation, strictly avoiding oil in the popping chamber, adhering to manufacturer guidelines, allowing for cool-down periods, and performing regular maintenance—you can significantly minimize the risk of overheating. Prioritizing these practices will not only safeguard your appliance but also ensure many years of delicious, worry-free air-popped popcorn. What’s your favorite healthy popcorn topping to enjoy with your safely popped kernels?

Frequently Asked Questions

Can an air popper catch fire from overheating?

An air popper can pose a fire risk if it overheats significantly, especially if operated improperly, left unattended, or if combustible materials (like oil) are mistakenly added to the popping chamber. Proper use and ventilation are crucial to prevent this and ensure safe operation.

How long can I run my air popper continuously?

Most air poppers are not designed for continuous operation. It’s generally recommended to allow the unit to cool down for at least 10-15 minutes between batches to prevent overheating and prolong its lifespan. Always check your specific model’s manual for precise guidelines.

Why does my air popper smell like burning plastic?

A burning plastic smell often indicates that the unit is overheating, possibly due to obstructed vents, internal component issues, or the presence of foreign material. If you detect this smell, unplug the machine immediately, let it cool completely, and inspect for any visible damage. Do not use the appliance if the smell persists or if damage is found.

Is it normal for an air popper to get very hot during use?

Yes, air poppers generate considerable heat to pop kernels efficiently, so the exterior and internal components will become hot during operation. However, excessive heat beyond normal operating temperatures, particularly if accompanied by smoke, unusual odors, or loud noises, is a clear sign of overheating and requires immediate attention.