For many, popcorn is synonymous with movie nights and cozy evenings. But with so many options available, from microwave bags to various popping machines, finding the perfect method for a healthy yet delicious snack can be a challenge. If you’re looking for an easy, oil-free way to enjoy your favorite kernels, the Toastmaster Air Popcorn Popper stands out as a popular choice. This review will delve into its features, performance, and whether it’s the ideal addition to your kitchen.

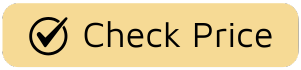

Decoding Popcorn Makers: A Quick Overview

Before we dive into the specifics of the Toastmaster Air Popcorn Popper, let’s briefly understand the different types of popcorn makers available and their unique characteristics. This can help you appreciate what makes an air popper distinct.

Stovetop Popcorn Makers

These are the traditionalists’ choice, often featuring a pot with a stirring mechanism.

- Pros: Generally affordable, offer excellent control over popping temperature, and allow for hands-on flavor adjustment.

- Cons: Require constant supervision to prevent burning, and cleanup can be more involved.

- Best for: Individuals who enjoy a traditional popping experience and wish to customize their popcorn’s flavor and texture precisely.

Air Poppers

As the name suggests, these machines use hot air to pop kernels, eliminating the need for oil.

- Pros: A healthier snack option due to the absence of added oils, and they typically pop corn very quickly.

- Cons: The resulting popcorn can sometimes be a bit drier or have less inherent flavor compared to oil-popped varieties, and adding seasonings can be trickier.

- Best for: Health-conscious individuals looking to reduce calorie intake and those who prioritize speed and convenience.

Oil Poppers

These machines use a small amount of oil to pop kernels, often featuring a stirring rod to ensure even popping.

- Pros: Produce wonderfully crispy and flavorful popcorn, and they make it easy to incorporate seasonings during the popping process.

- Cons: Require oil, which means a higher calorie count, and can be slightly messier to clean than air poppers.

- Best for: Popcorn enthusiasts who love the classic movie-theater taste and don’t mind a bit of oil for a richer flavor.

Popcorn Maker Comparison Table

To help you quickly grasp the differences, here’s a comparison of the main types of popcorn makers:

| Feature | Stovetop | Air Popper | Oil Popper |

|---|---|---|---|

| Price | Low | Medium | Medium |

| Health | Medium | High | Low |

| Flavor | Customizable | Limited | Rich, Flavorful |

| Ease of Use | Medium | Easy | Easy |

| Cleaning | Difficult | Easy | Medium |

Illustration showing different types of popcorn makers: stovetop, air popper, and oil popper.

Illustration showing different types of popcorn makers: stovetop, air popper, and oil popper.

Toastmaster Air Popcorn Popper: A Closer Look at the TM-202PC Model

The Toastmaster Mini Air Popcorn Popper, often identified by its model number TM-202PC, is designed to deliver a convenient and healthy popcorn experience. This compact appliance aims to make homemade popcorn a hassle-free delight for individuals and small families.

Design & Build

The Toastmaster Air Popcorn Popper boasts a compact and space-saving design, making it an excellent fit for smaller kitchens or for those with limited counter space. Its sleek black plastic construction ensures durability, and importantly, it is BPA-free, addressing a common concern for health-conscious consumers. The minimalist aesthetic allows it to blend seamlessly with most kitchen decors.

Key Features & Performance

At the heart of the Toastmaster Air Popcorn Popper’s appeal is its straightforward operation and effective performance.

- One-Touch Operation: Simplicity is key with this machine. With just one touch, you can initiate the popping process, making it incredibly user-friendly for all ages.

- Capacity: Designed primarily for individual servings, couples, or small families, this air popper can produce up to 6-8 cups of fluffy popcorn in minutes. It’s ideal for a quick snack or a small movie night gathering. However, for larger groups, you might find yourself running multiple batches.

- Power and Speed: Operating at 800 watts, the Toastmaster Air Popcorn Popper heats up quickly and efficiently, ensuring your popcorn is ready in just a few minutes.

- Butter Melting Tray: A thoughtful addition is the integrated kernel scoop that ingeniously doubles as a butter melting tray. Placed on top of the popper, it uses the residual heat to soften butter, which can then be drizzled over your freshly popped corn. While convenient, some users note that butter may not melt completely, and for perfectly liquid butter, a separate melting process might be preferred.

- Easy Cleaning: The removable upper chute and cover significantly simplify the cleaning process. Most of the time, a simple wipe-down is all that’s needed, saving you precious time after enjoying your snack.

- Noise and Vibration: User experiences regarding noise levels are somewhat mixed; some find it quiet, while others describe it as quite loud during operation. A more notable point of feedback is the machine’s tendency to vibrate significantly. Some users have found it necessary to hold the popper to prevent it from moving or potentially falling off the counter, which is a consideration for safety and convenience.

- Kernel Efficiency: While it generally produces fluffy and crisp popcorn, a common critique points to a decent number of unpopped kernels remaining and, occasionally, some kernels flying out of the chute during the popping process. Using a larger bowl and positioning it correctly can help mitigate the latter issue.

Close-up of Toastmaster air popcorn popper showing butter melting tray and chute.

Close-up of Toastmaster air popcorn popper showing butter melting tray and chute.

Is the Toastmaster Air Popcorn Popper Right for You?

Considering its features and performance, the Toastmaster Air Popcorn Popper is an excellent choice for several types of users:

- Individuals or Small Families: Its 6-8 cup capacity is perfectly suited for preparing snacks for one or two people, or a small household’s movie night.

- Health-Conscious Snackers: For those actively looking to reduce their fat and calorie intake, the oil-free popping method is a major advantage.

- Budget-Minded Consumers: The Toastmaster Air Popcorn Popper is an affordable option, offering a cost-effective way to enjoy fresh popcorn at home compared to pre-packaged microwave bags.

- Those with Limited Counter Space: Its compact footprint ensures it won’t overcrowd your kitchen, making it a practical appliance for smaller living spaces.

Maximizing Your Popcorn Experience

To get the best out of your Toastmaster Air Popcorn Popper, consider these tips:

- Choose Quality Kernels: The type and freshness of your popcorn kernels can significantly impact the final result. Invest in good quality, fresh kernels for maximum pop and minimal unpopped remnants.

- Use a Large Catch Bowl: To minimize any flying unpopped or popped kernels, ensure you place a sufficiently large bowl directly under the chute, and perhaps position it slightly elevated to catch everything.

- Season Separately: While the built-in butter melter is a neat idea, for fully melted butter or more complex seasonings, you might achieve better results by preparing them in a separate bowl and adding them after the popcorn has popped.

- Ensure Stability: Due to the reported vibration, it’s advisable to place the popper on a stable, non-slip surface. If significant movement occurs, gently holding it during operation can prevent accidents.

Conclusion

The Toastmaster Air Popcorn Popper offers a compelling package for anyone seeking a quick, healthy, and convenient way to make popcorn at home. Its compact design, ease of use, and oil-free operation make it a standout choice for health-conscious snackers and small households. While some minor drawbacks like noise and vibration exist, its overall value and performance make it a worthy contender in the world of Popcorn Makers. Ready to upgrade your snack game? The Toastmaster Air Popcorn Popper could be your ticket to delicious, guilt-free popcorn.

Frequently Asked Questions (FAQ)

How many servings does the Toastmaster Air Popcorn Popper make?

The Toastmaster Air Popcorn Popper is designed to make up to 6-8 cups of popped popcorn per batch, which is ideal for single servings, a couple, or a small family. It may require multiple batches for larger gatherings.

Is the Toastmaster Air Popcorn Popper loud during operation?

Feedback on the noise level varies among users. Some describe it as quiet, while others report it can be quite loud. It’s generally comparable to other air poppers in terms of noise.

Do I need oil to pop corn with this machine?

No, the Toastmaster Air Popcorn Popper uses hot air to pop kernels, meaning no oil is required for the popping process itself. This makes it a healthier option for snack preparation.

How do I clean my Toastmaster Air Popcorn Popper?

Cleaning is straightforward. The upper chute and cover are removable and can be easily wiped down. The main unit usually only needs a quick wipe to remove any kernel dust or residue.

Can I melt butter directly in the machine?

Yes, the Toastmaster Air Popcorn Popper includes a kernel scoop that also functions as a butter melting tray, placed on top of the unit. However, some users note that butter may not melt completely, and for fully liquid butter, melting it separately might be more effective.